About Spray Chrome

In years past, chrome car parts were made by electro-plating chrome onto steel or other metal. The type of chrome used for this is toxic and poses many environmental challenges. Silver is less toxic to humans and subject to fewer environmental regulations. Using silver to 'chrome' an object can be easier than electroplating but it has its own challenges.

Many thanks to Gaylon Janes for allowing us to show off the side covers he spray chromed for his Goldwing Trike using 2-Part Spray Silver and Clear Uni-Coat.

We also thank Gordon Tarpley for allowing us to show his spray chromed cosplay boots as part of his C3PO costume.

What is spray chrome?

Spray chrome is not chrome. It is a front surface silver mirror - meaning that the silver is on top of the object rather than viewed through layer of glass.

Spray chrome is not silver paint. It is a chemical reaction that takes place on the surface of the piece as you apply it. Because it is a chemical reaction, there are important steps you need to take to get good results.

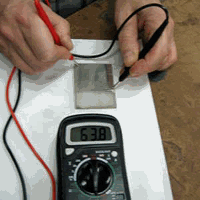

Using silver for electroplating

If you would like to electro-plate a non-conductive surface with real chrome or any other metal, see our page on Electroplating and Powder Coating to see how you can use our silver instead of a heavy conductive paint to make this happen.→

Suitable surfaces

- You cannot silver directly onto a metal surface. You must coat a metal object with a non-conductive base coat first.

- You can silver any non-conductive, non-porous surface. Silvering does not change the surface texture.

- You can silver a porous surface, such as wood or plaster, if you seal it first with a few coats of Uni-Coat. The number of coats you need to create a hard, glass-like surface will depend on the porosity of the material you are coating.

- Silver does not make a dull surface look like a mirror. The surface must be very high gloss - like glass - before you silver it.

- You do not need to apply a base coat to plastic surfaces if the plastic is already high gloss. See our Troubleshooting Guide for more information.

Protecting the silver

Unlike chrome, silver tarnishes and turns black when exposed to the air. The silver layer created by the mirroring process is 50 to 100 nanometers thick - about 600 times thinner than a human hair. It must be protected after it is applied.

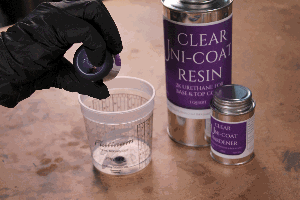

Top coat notes

You must protect the silver a with clear coat.

The clear coat must be chemically compatible with the base coat.

For a pure silver look, tint the clear coat with a transparent violet dye.

Use other tints for a brilliant 'candy coating'. Use a yellow tint to make the object look like gold.

Silver covered by a clear coat will never look as brilliant as bare silver or chrome.

Why tint the top coat?

Next time that you silver something - glass or plastic - look at the wet and dry areas. The wet silver looks pale yellow and the dry silver looks brilliant blue-white. Any clear coating on a thin layer of silver, whether it is distilled water or crystal clear urethane, makes the silver look yellow. This is the result of an optical phenomon called Rayleigh scattering. The silver looks yellow because the blue wave lengths of light are trapped and scattered in the top coat. It is the same reason why sunlight looks yellow and the sky looks blue.

The only way to counteract this effect is to add a transparent blue or violet dye to the top coat. In terms of light, blue is the color opposite of yellow. However, many blue tints start to look green when they are very diluted; the red in violet tints counteracts the green to give a true silver color.

Pouring Silver or Spray Silver?

We have 2 silver formulas - pouring and spraying. The silver they deposit is exactly the same but the application method is different. Pouring silver often leaves a slight haze on the silver surface. To remove this haze:

Use a clean real leather chamois.

Get it sopping wet with distilled or de-ionized water.

Lightly and gently stroke the silver.

Rinse the burnished silver with a spray of distilled or de-ionized water.