Electroplating and Powder Coating

Silver conducts electricity. Any silver-coated surface, whether it is plastic, ceramic or glass, is electrically active. Once the surface is silvered, you can powder coat it or electroplate it. You can use any of our mirror kits to silver any non-metallic surface if you would like to electroplate your car part with real chrome. Caswell Plating sells many types of kits for small scale electroplating.

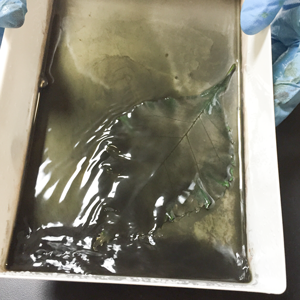

Conductive paints often change the gloss and texture of the surface. Our silver does not does not change the original texture of the surface in any way. It does not make a rough surface smooth or a dull surface shiny.

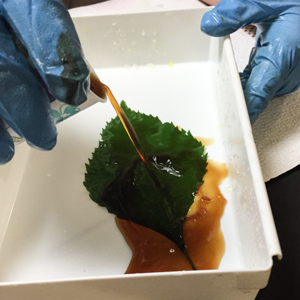

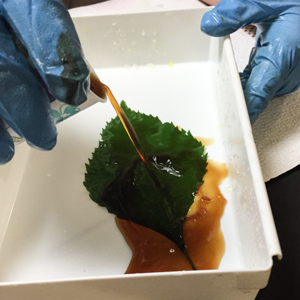

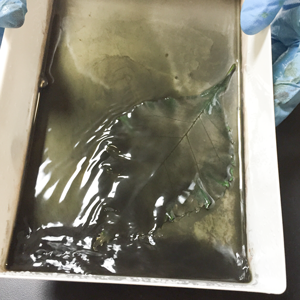

In this photo, the multimeter shows that the resistance across this silvered leaf is 75.3 ohms.

General Tips

- Wear gloves at all times to keep your fingerprints off the surface.

- Silvering is a wet process. Seal porous objects first with a penetrating sealer.

- Rinse the silvered surface thoroughly before placing it in the electroplating tank.

- Be sure that the wire touches the silvered surface without scratching it.

- Enclose small objects in a wire cage.

- Nickel is the best metal to plate over our silver. You can plate any metal, including gold, over the nickel in a second plating bath.

Voltage and Time

- Begin by using the lowest voltage possible - about 2.7 volts.

- Use about 1/10 amp per square inch.

- Plate the object for at least one hour. Two hours usually produces a good thick coat.

- Test the thickness of the coat with your fingernail. If you can scrape it off, put the object back in the bath and continue plating.

Adding Additional Coats

When the object has a good coat of nickel, you can buff it to a high shine with jeweler's rouge and a polishing wheel before brush or tank plating it with other metals.

For chrome plating, first silver the object, then nickel plate it, then chrome plate it. Unlike "spray chrome", this process does not require a protective top coat.

Brush Plating

The silver coat you get from our mirroring chemicals is too thin for brush plating. If you want to brush plate an object, you must tank plate it with nickel first.

Powder Coating

When you coat a plastic part with silver, you do not need to heat it to make the powder coating stick. Just dry the silver completely and apply the powder coating directly over the bare silver.

Silvering to Prepare for Electroplating

- Silvering chemicals will not flow evenly over hydrophobic surfaces such as plastics. Use Wetting Agent to break the surface tension to achieve a more even coating.

- Any of our silvering chemicals will deposit the silver layer to make your piece conductive. The method of silvering depends more on method of application based on the dimensions of your piece.

- Silver deposited by the mirroring process is incredibly thin. Plan to electroplate your piece soon after applying the silvering to avoid degredation of the silver.

- Many of our kits include backing paint. Do not paint the silver surface with a backing paint prior to electroplating.

The silvering process below is shown from time stamp 1:40 to 2:08.