About Silver Mirrors

You can silver any substrate except bare metal. You can silver wood, glass, plastic or glazed ceramic.

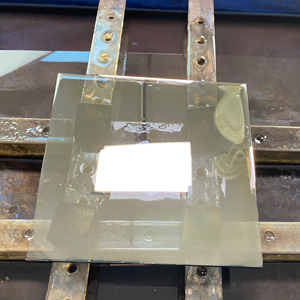

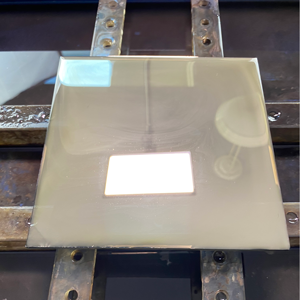

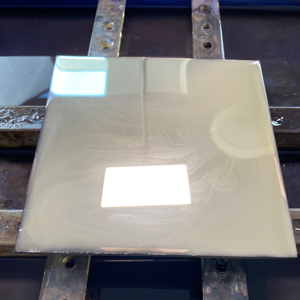

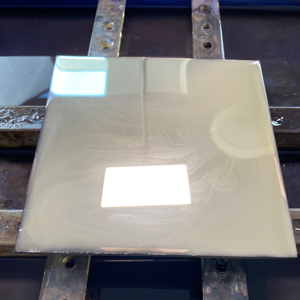

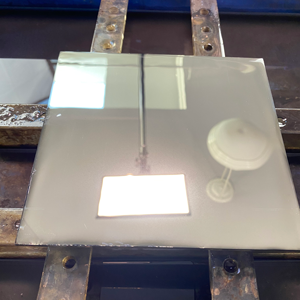

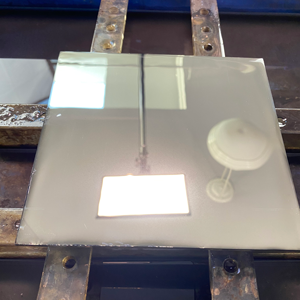

Silver by itself does not make a surface look like a mirror. The surface that you silver must be as glossy as possible - as shiny as glass.

Silver mirrors are easy to make

- You can easily identify problems because you know what a silver mirror should look like.

- Silver only needs one sensitizer.

- Silver deposits faster than other metals.

- We have two silver formulas. Pouring Silver reacts in about 5 minutes. Spray Silver reacts in 5 to 10 seconds.

- The application methods for the two formulas are different. The final silver coat is exactly the same.

Pouring Silver

- The slower reaction time allows you to control the process.

- You have time to "antique" the silver while it is forming.

- You can get an even deposit inside a glass container.

- There is no over-spray or mist in the air.

- The front surface (the silvered side) is slightly less reflective than Spray Silver.

- It can be difficult to produce a uniform coating on large sheets of glass.

- Pouring Silver Concentrate is the pre-diluted version of Pouring Silver Ready-To-Use.

Spray Silver

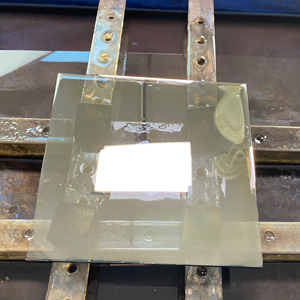

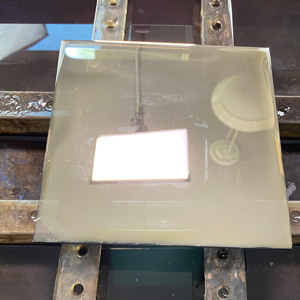

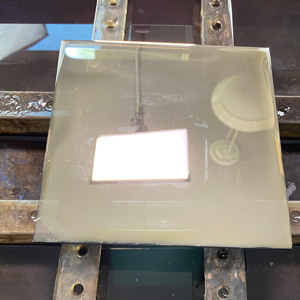

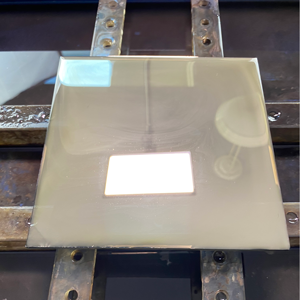

- Spraying produces a more uniform deposit over a large area.

- The front surface (the silvered side) is brilliantly reflective.

- You can mirror any size or shape or texture.

- You need a dedicated workshop and an air compressor to use Spray Guns.

- You do not need an air compressor to use our Pump Spray Silver Kit or Drip Silver Kit.

Applications for Pouring Silver

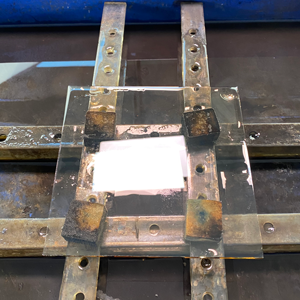

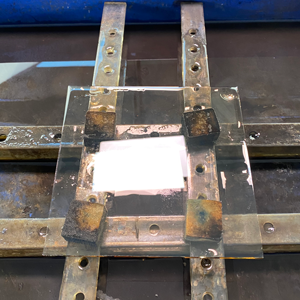

Pouring Silver is ideally suited for most flat glass applications. To ensure that your flat glass piece is suitable for the Pouring Silver processes, ensure that you can support the glass in a tray to capture the waste water and are able to gently rock the tray for approximately 3-5 minutes.

Pouring Silver requires that you are able to allow the chemicals to sit on the surface for approximately 3-5 minutes. Due to this, silvering curved glass is not suited for the Pouring method as gravity works against this requirement.

When your piece is small and irregular in shape (such as an automotive rearview mirror, a small beveled glass, or a sextant prism) you can use Pouring Silver in the shallow bath technique. This enables the piece to sit in a tray while the chemicals are gently rocking over the piece. This is not suitable for items with a curvature or dimension larger than what could reasonably "wash" over a piece continuously for 3-5 minutes.

Blown glass objects that are to be silvered on the outside do very well in the pouring method. You will need to temporarily cover the opening of the piece to allow the chemicals to evenly rock around inside of the piece. We find the best way to do this is with our Evalite Foam.

Pouring Silver is not intended for front surface mirroring. The mirror layer produced with the Pouring Silver chemicals is not intended to have maximum optical quality on a front surface.

Applications for Spray Silver

Spray Silver is a great way to silver large pieces of flat glass (and other substrates). Some Antiquing processes work best with the spray technique. Depending on your needs we have both the Pump Spray Assembly setup and the Air Compressor Required Setup. The Pump Spray Assembly does not require access to an air compressor or electricity. The Spray Silver Kit utilizes air hoses that connect into your air compressor and is best for production setups.

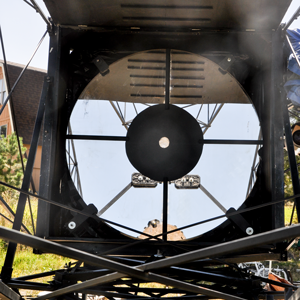

Curved glass is ideally suited for Spray Silver as you do not need to worry as much about gravity pulling the solution off the piece. Depending on the size and shape of the curves we have three kits to offer.

When your piece is small yet has some dimension to it you can utilize the benefits of the Spray Silver's quick development speed with the precise action of our Siphon Drip System. Don't worry about overspray here, the Siphon delivers the chemicals in a joint flow over your piece.

Spray Silver is not suitable for the interior of Blown Glass containers. The speed of the deposit does not allow for a complete coverage of an even silver layer.

Spray Silver chemicals are ideally suited for front surface mirroring. They create essentially the same silver appearance on both the front surface and second surface of a piece. We provide different kits depending on the size of the pieces you plan to silver.

Compare 2-Part & 3-Part Spray Silver

2-Part Spray Silver

- Simple mixing instructions - product does not include Silver Activator

- Sensitizer for 2-Part Spray Silver is highly concentrated and has a shelf life of about 1 year.

- Product has a strong odor of ammonia

- 2-Part Spray Silver is included in our Pump Spray, Drip Silver and Spray Silver Kits

3-Part Spray Silver

- You must mix Silver Solution with Silver Activator before using

- Product has a weak odor of ammonia

- You can use Sensitizer for 2-Part Spray Silver with 3-Part Spray SIlver